From Grid to Field—We Power the Infrastructure That Powers the World

Powering Reliability and Safety in Utility Infrastructure

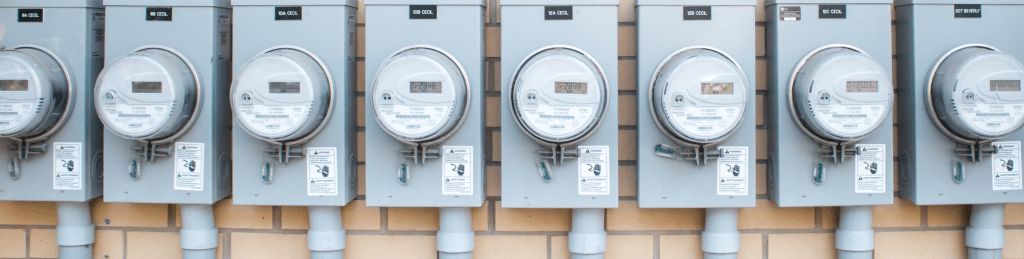

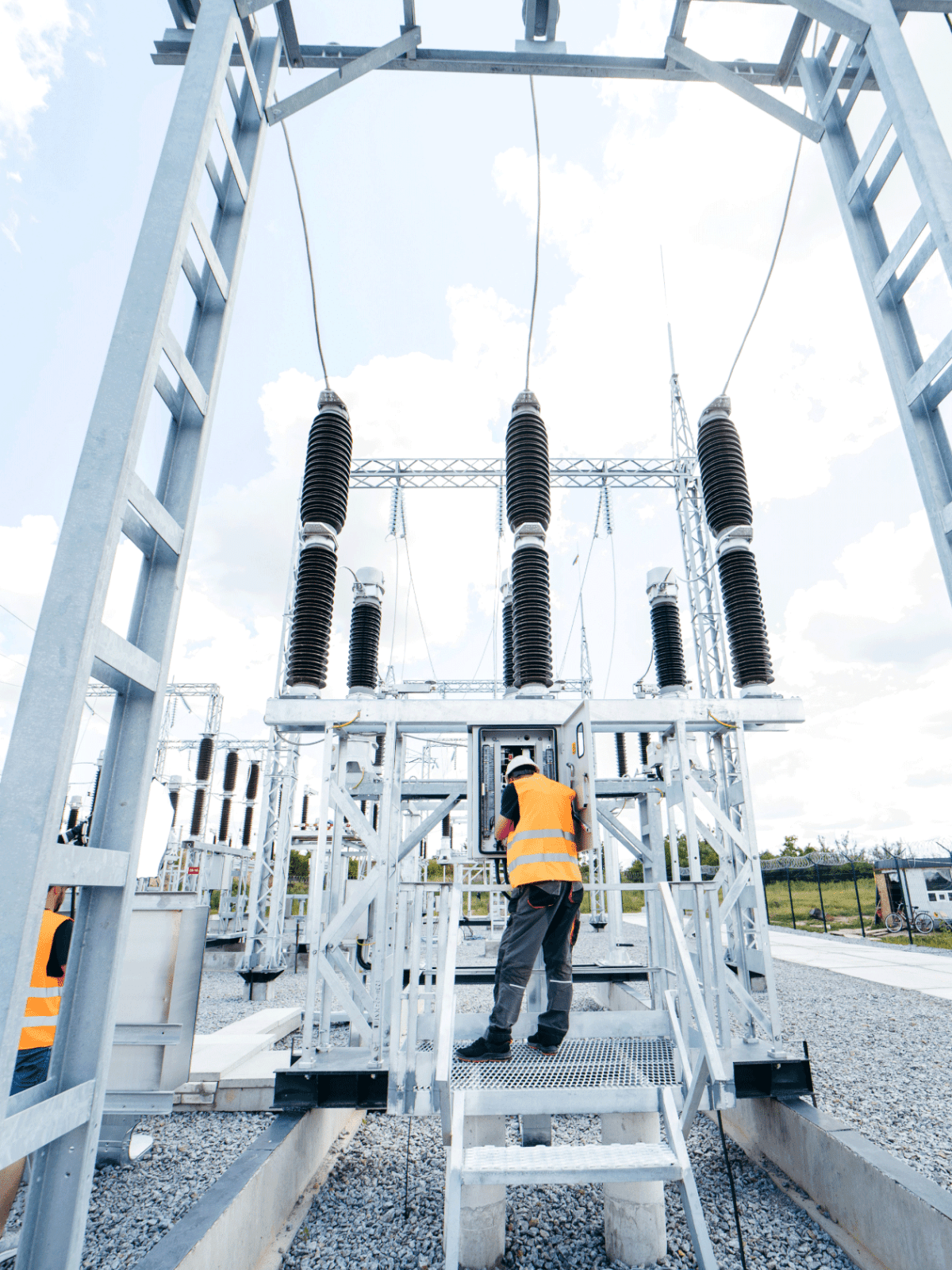

Modern utility systems, including power generation, water treatment, and grid infrastructure, demand rugged, intelligent components that can operate reliably in harsh environments and mission-critical applications. These systems require precise sensing, robust switching, and high-voltage isolation to support automation, monitoring, and safety across diverse utility networks.

Our solutions are engineered to meet these challenges, delivering long-term durability, environmental resilience, and compact integration for utility-grade platforms.

The following are core technology applications that support safe and reliable operation in utility systems:

Technology Portfolio for Utilities:

- Reed Relays: High-isolation, low-leakage switching for signal routing, fault detection, and control logic in grid and substation systems.

- Reed Switches & Sensors: Hermetically sealed, contactless sensing for enclosure monitoring, valve position, and safety interlocks in water, gas, and power infrastructure.

- Hall Effect Sensors: Solid-state sensing for current, position, and motion feedback in smart meters, actuators, and automated utility equipment.

- Optocouplers: Electrical isolation and EMI protection in high-voltage, high-noise environments such as substations and control panels.

- Custom Assemblies: Integrated sensor and relay solutions tailored for utility-grade enclosures, monitoring systems, and field-deployable platforms.

Engineering Reliability into Every Connection

Standex Detect: Your Engineering Partner in Utility Infrastructure

At Standex Detect, we don’t just manufacture components, we become an extension of your engineering team. Through our Innovate | Consult | Engineer | Deliver approach, we collaborate with utility OEMs, integrators, and infrastructure providers to co-engineer scalable, reliable solutions that meet the demands of modern utility systems.

Our approach is built on four pillars that guide every engagement:

- Innovate: Generate new ideas and technologies that solve emerging challenges in grid modernization, environmental monitoring, and electrification.

- Consult: Understand client needs and regulatory requirements through open dialogue and technical intimacy, ensuring every solution is fit for purpose.

- Engineer: Create effective and tangible solutions through deep technical collaboration and application-specific expertise in power, water, and gas infrastructure.

- Deliver: Ensure customer satisfaction with solutions that meet performance, quality, and delivery expectations, even in the most demanding utility environments.

Whether you’re designing for smart grid platforms, water treatment automation, substation monitoring, or field-deployed control systems, we bring the agility, customization, and global support needed to help you succeed in mission-critical environments.

What Sets Us Apart

- Engineer-to-Engineer Collaboration: We work directly with your technical teams to co-develop solutions that meet your exact specifications for utility-grade performance and compliance.

- Vertically Integrated Manufacturing: From reed switches to custom sensor assemblies, we control the entire production process, ensuring quality, traceability, and speed.

- Agile Global Supply Chain: With 18 sites across 3 continents, we offer local support, redundancy, and rapid response to changing infrastructure demands.

- Custom + Standard Solutions: Whether you need off-the-shelf components or fully customized assemblies, we deliver both with precision and speed, tailored to utility applications.

Why Utility OEMs Choose Us

- Custom Engineering: From discrete components to integrated assemblies, tailored for utility-specific applications.

- Agility & Speed: Fast response to design changes, regulatory shifts, and field conditions, supporting rapid deployment and compliance.

- Reliability: Components tested for extreme temperatures, vibration, moisture, and long-term outdoor exposure.

- Scalability: From pilot programs to nationwide infrastructure rollouts, our solutions scale with your utility platform.

- Innovation: Smart sensing, high-voltage isolation, and ruggedized designs for next-generation utility systems.

Certified, Customizable, and Built for Critical Infrastructure

Certifications & Compliance

We meet or exceed globally recognized standards to ensure the safety, reliability, and performance of our reed switches, sensors, and relays in utility applications, from fluid monitoring to hazardous oil and gas environments:

General Utilities:

ISO 9001:2015 – Quality Management System

ISO 14001:2015 – Environmental Management System

REACH & RoHS – Compliance with hazardous substance and environmental regulations

CE Marking – Conformity with EU safety, health, and environmental protection standards

Oil & Gas:

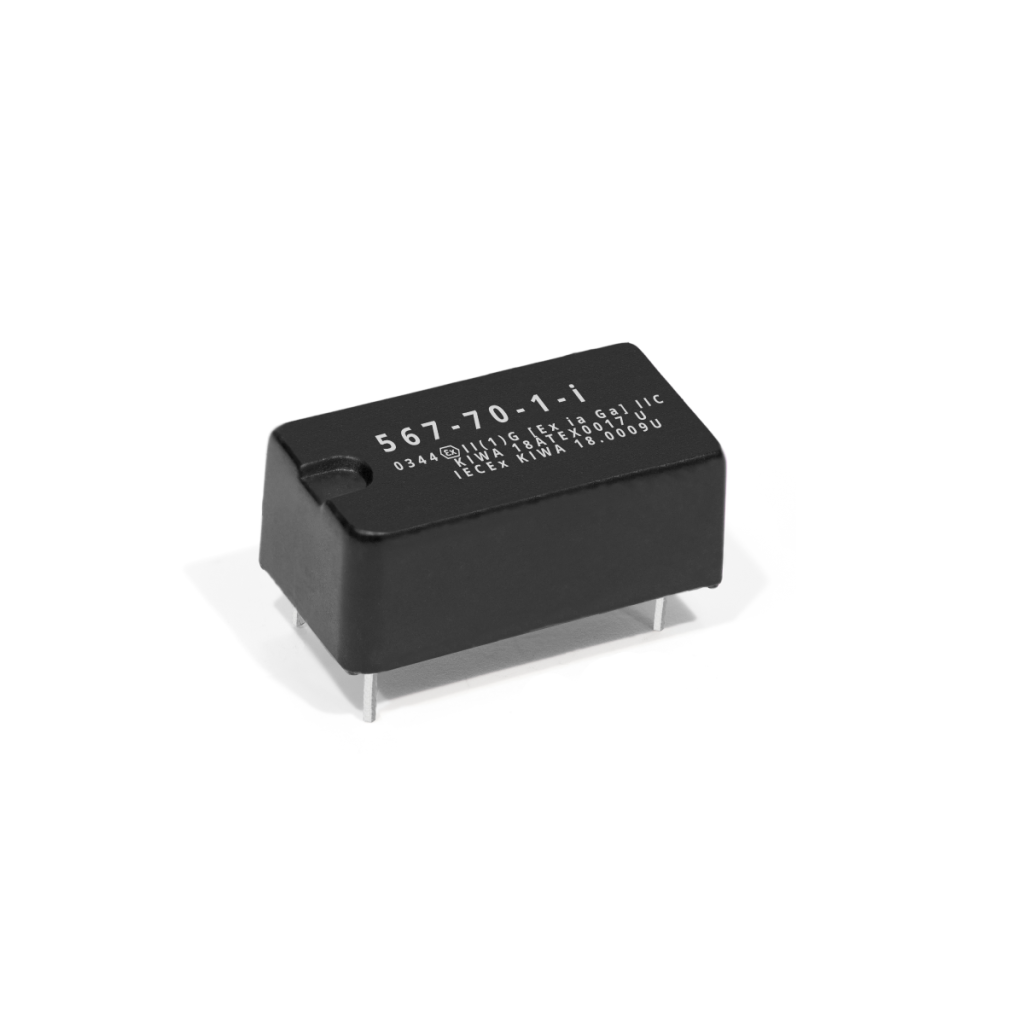

ATEX & IECEx – Certified for use in hazardous and potentially explosive environments

DIN EN ISO/IEC 80079-34 – Quality systems for explosive atmospheres

UL Certification – For intrinsically safe reed sensors used in oil and gas applications

Monitoring:

IP65/IP68 Ratings – Environmental protection for liquid level sensors used in tanks, reservoirs, and utility systems

UL Recognized Components – For fluid level detection in industrial and utility monitoring systems

Case Study

Solar Energy Pioneer Shines Bright

A solar inverter manufacturer needed a reed relay with 1,500V switching voltage and 15mm creepage distance. Standex delivered a custom solution that met high-voltage and environmental demands for solar applications.

Challenge:

A solar inverter OEM required a reed relay capable of switching 1,500V with 15mm creepage distance for high-voltage solar applications.

Solution:

Standex developed a custom high-voltage reed relay that met all electrical and environmental demands.

Outcome:

- Enabled safe, efficient operation in solar inverters

- Met international safety and performance standards

- Supported rapid deployment in renewable energy projects