Electrifying the Road Ahead: High-Voltage Isolation and Intelligent Sensing for EV Platforms

Compact, Certified Sensor and Relay Solutions for Battery, Thermal, and Power Systems

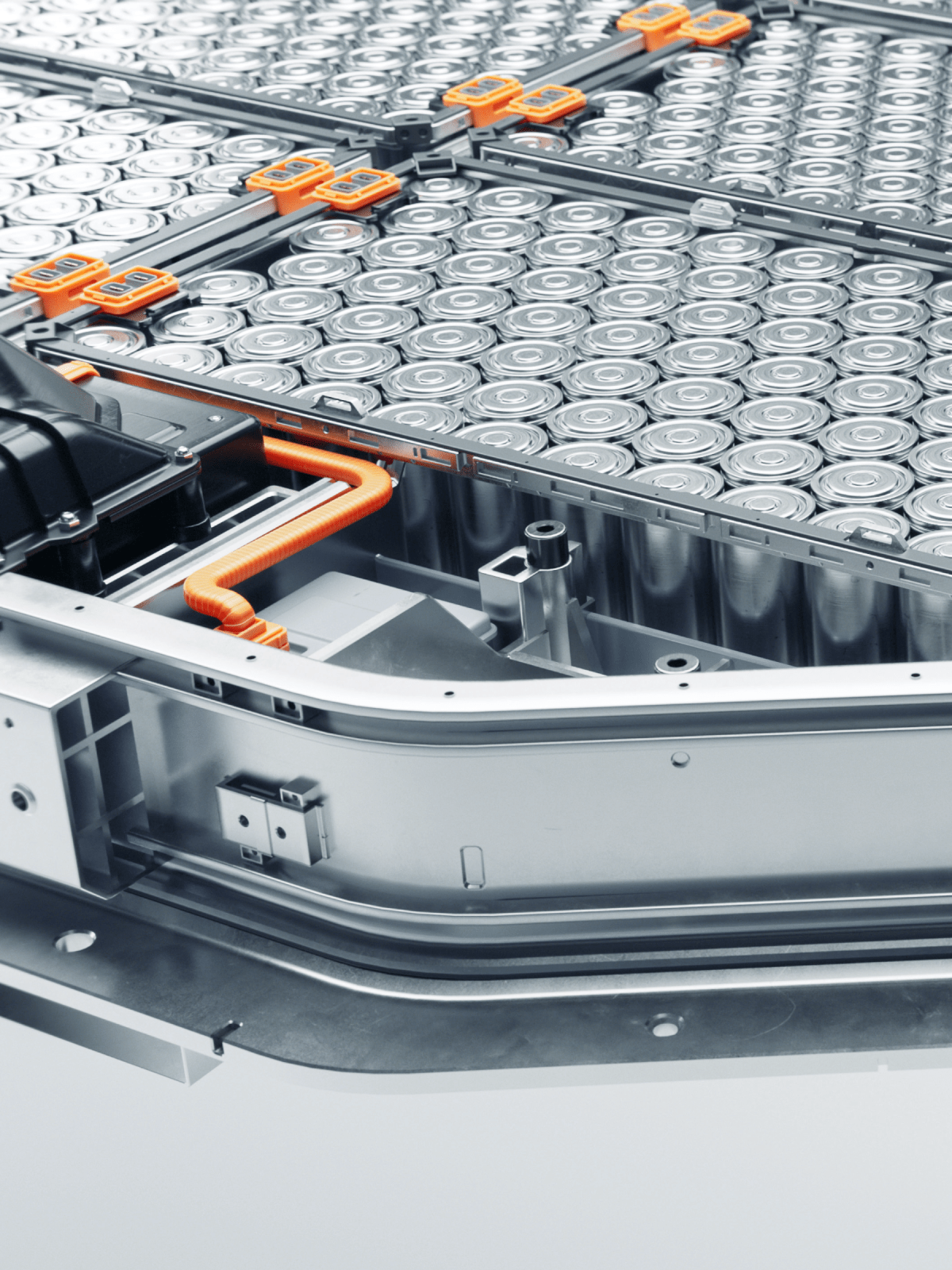

Electric vehicles (EVs) are redefining the future of mobility, placing new demands on component performance, safety, and integration. With high-voltage systems, complex thermal management, and increasing digitalization, EV platforms require compact, certified components that can operate reliably under demanding conditions. From battery safety to cabin comfort, advanced reed switches, sensors, and relays are essential to ensure efficiency, protection, and a seamless user experience.

The following are core technology applications that support the evolving needs of electric vehicle systems:

Core Capabilities for E-Vehicles:

- Thermal management systems: Hall sensors monitor coolant flow and pump speed.

- Onboard charger safety interlocks: Reed switches detect connector engagement.

- Inverter and motor control isolation: Optocouplers protect low-voltage control circuits.

- Cabin pre-conditioning systems: Relays manage HVAC and seat heating circuits.

- Battery pack intrusion detection: Reed sensors detect tampering or unauthorized access.

Engineered for Safety, Efficiency, and Integration

Why Partner with Standex Detect for E-Vehicles

Electric vehicles require efficient, high-performance sensors for battery management, charging, and system control. Our solutions support the transition to cleaner mobility.

- Proven performance in vibration-heavy environments

- Custom solutions for EV platforms

- Compact sensors for embedded electric systems

- Global engineering support and rapid prototyping

Certifications & Compliance

ISO 9001 – Quality management

RoHS – Environmental compliance

IP67-rated designs – Dust and water resistance

UL & CE – Electrical safety

REACH – Chemical safety compliance

IATF 16949 – Automotive quality management

Case Study

A Top Manufacturer of Premium E-Vehicles Makes it All Fit

Challenge:

A leading German manufacturer of premium electric vehicles (EVs) faced a major design constraint: fitting multiple sensors into a compact footprint on their printed circuit board (PCB). Their initial choice, the KT Reed Relay, was too large to accommodate three units within the available space, threatening to derail the design and delay production.

Solution:

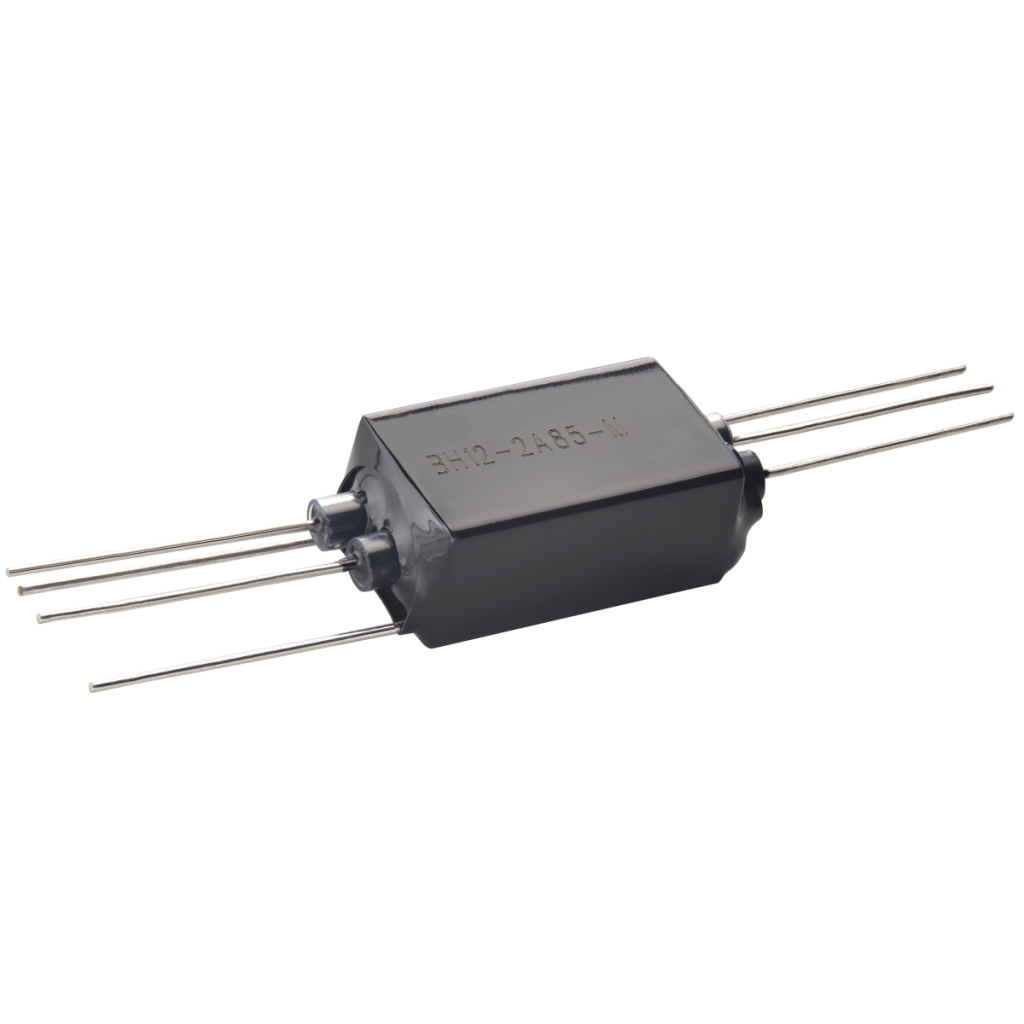

Standex Detect collaborated closely with the manufacturer to identify a better fit. They introduced the MHV Reed Relay, one of the smallest reed switches in the world, smaller than a U.S. penny. This ultra-compact, hermetically sealed relay met the size, durability, and energy efficiency requirements without needing a full redesign of the PCB.

Outcome:

- The client avoided a costly and time-consuming redesign.

- The MHV Relay enabled the team to meet aggressive delivery timelines.

- The solution provided long-lasting, rugged performance with zero energy consumption in passive states.

- The partnership was strengthened by Standex’s hands-on engineering support and willingness to assist beyond their own components.