“Magnetic Sensors Tackle a Broad Range of Smart Sensing Applications”

If there are particular areas you need help with, feel free to skip to any of the following sections:

Introduction

Magnetic Sensors Pair with Electronics for Remote Monitoring

Types of Magnetic Activated Sensors

How a Magnetic Sensor Works

Conclusion

Additional Resources

Introduction

Monitoring anything in real time using remote signals is a growing trend for magnetic sensors. They detect and monitor key variables in a broad range of applications. Sensing applications include security, industrial processes, transportation equipment, commercial, industrial, and residential buildings.

Magnetic Sensors Pair with Electronics for Remote Monitoring

Today’s magnetic sensors are paired with electronics which allow remote monitoring. Instead of simply sensing the door position, sensors now remotely control door locks. The same sensor paired with a card reader can control individual access to specific rooms. Additionally, the sensor confirms that the door has returned to its locked state.

Remote door sensors also monitor ship container assets using battery operated wireless sensors. Furthermore, sensors paired with GPS electronics provide 24 hour asset tracking. Similarly, heavy-duty trucks use magnetic sensors to remotely monitor critical assets.

Magnetic sensors are widely used in detecting position, fluid flow and level, utility metering, and pressure. Magnets are the actuator in the sensing element. Permanent magnets are readily available, inexpensive and very stable. Additionally, these magnets can also be very stable in harsh environments when properly designed. Properties the make magnetically activated sensors a popular choice in today’s sensing market.

Types of Magnetically Activated Sensors

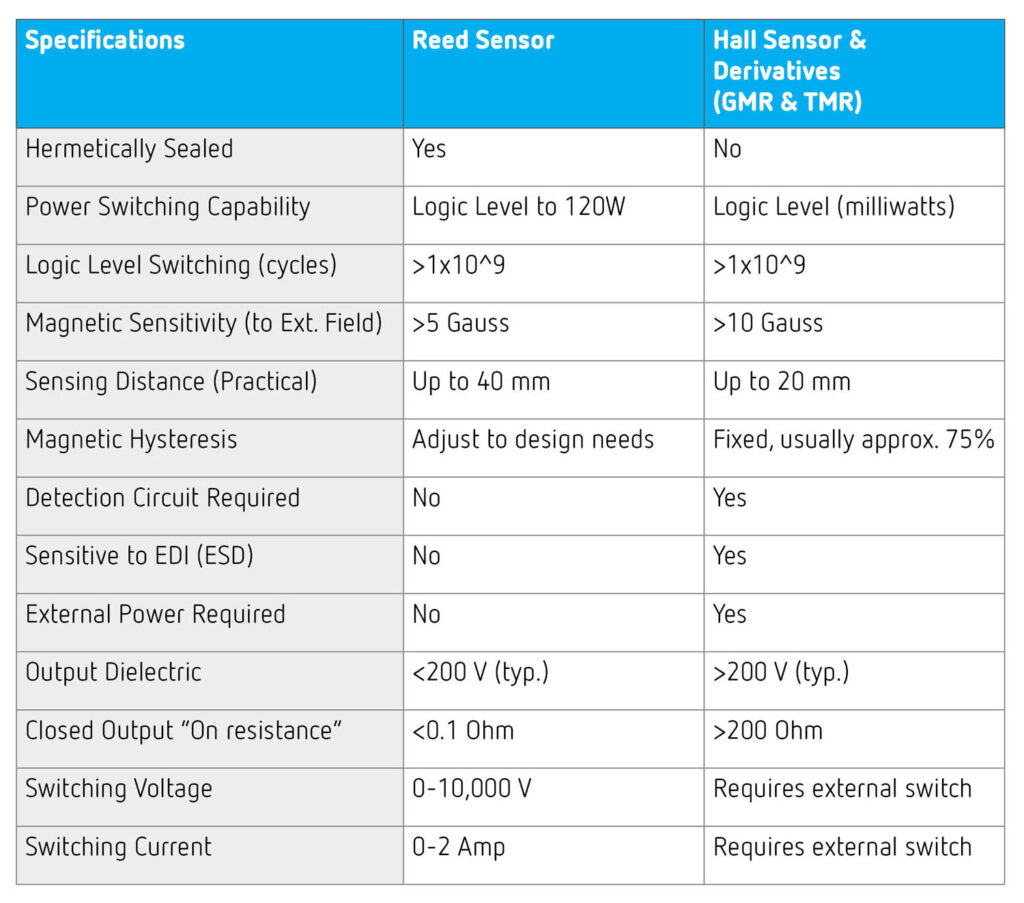

Types of magnetically activated sensors include Reed sensors, Hall effect sensors (and their derivatives), Wiegand sensors. Some even include current transformers used in analog sensor applications. Some analog applications use Hall Sensors. The vast majority of magnetically based sensors use Reed or Hall Effect for their attributes shown below.

Both Hall Sensors and Reed Sensors play a major role in the magnetic sensor marketplace. Hall sensors are somewhat smaller solid state devices that always require external power and have the disadvantage of requiring external EDI protection as well as external switches and/or drivers to allow switching any appreciable electrical load. They do not in themselves have the ability to withstand external electrical surges.

Reed Sensors are usually larger than Hall Sensors but have unique switching capability up to 10 VA. Versions of Reed Sensors have the ability to switch over 100 VA directly. They also have substantial ability to withstand electrical surges.

How a Magnetic Sensor Works

When applying these sensors in a specific application one must understand how the sensor sees the magnetic flux generated by the permanent magnet. Hall Sensors, to operate efficiently, must see the lines of magnetic flux generated by the permanent magnet perpendicular to a very small sensing area on the surface of the Hall Sensor.

Conversely, Reed Sensors ferromagnetic leads act as built-in flux concentrators searching for the flux generated by the permanent magnet. Furthermore, the switch leads can “grab” even more magnetic flux when modified. Like how a keeper functions on a permanent magnet.

Because Hall sensors come in somewhat smaller designs they tend to be easier to place mechanically. However, Hall sensors are typically less sensitive than Reed sensors. Reed Switch leads are ferromagnetic due to their NiFe plating. Magnetic circuit designs may take full advantage of the Reeds ferromagnetic ability.

Conclusion

Applying magnetic sensors to get the most from the sensor in real world applications is somewhat of an art. Some manufacturers have application design groups for designing complex magnetic circuits. Complex circuits contain magnetic variables that determine how these sensors will be used.

One of the more important technical services some manufacturers offer is magnetic circuit modeling and mapping. These systems guide the proper placement of various magnetic components mechanically in the end device.

Design of Experiment (DOE) is another analytical way for designing a magnetic sensor into the total magnetic circuit. DOE takes into account all the important magnetic and mechanical system variables. And the effect each has on the proper operation of the sensor system.

In summary, Standex Electronics is a magnetic sensing expert. We use proprietary magnetic mapping equipment to design an optimum sensor solution.

Contact us today, to discover how we can partner to deliver smart solutions for your project!

Additional Resources

For more information, see our Magnetic Sensor Technologies Infographic or download the full write-up on Smart World Sensors.