The ability to monitor the status of almost anything in real time using new, remotely addressable systems is exploding the need for sensors. These sensors can detect and monitor key variables in a broad range of applications including security, industrial processes, transportation equipment, commercial and industrial buildings and even within our own homes.

A sensor that would previously simply monitor the status of a door being opened or closed is now sometimes married with a control system that allows remote locking of the door and confirms that action has occurred. The same sensor, when paired with a card reader, will also provide notification that the door allowed someone to enter a premise and whose card was used to make the entry. It will also confirm the door has returned to its locked and/or dead bolted condition.

Battery operated wireless sensors are also used on ship containers to monitor the status of doors on the ship’s container to ensure the container is not violated by an unauthorized person. When paired with a GPS system it is possible to know the location of the container 24/7. Similar systems are used in heavy-duty trucks and a broad range of similar applications in order to remotely monitor critical assets.

Looking at the broad range of sensor applications, it is apparent that a very large portion of these applications employ magnetic sensor technology as the basis for the sensor operation. General applications including position sensing, fluid flow, fluid level, utility metering, and pressure; all apply magnetic technology to a large degree. One of the reasons magnetic sensor applications are so broad is that permanent magnets (normally used with magnetic sensors) are readily available, inexpensive and have very stable magnetic properties over product life. These magnets can also be very stable in harsh environmental situations when properly designed.

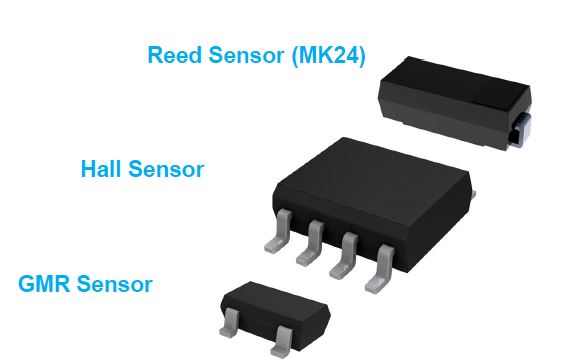

Magnetic technology based sensors include Reed Sensors, Hall Sensors (and their derivatives), Wiegand Sensors and some would even include current transformers sometimes used in analog sensor applications. Some Hall Sensors are also used in analog applications. The vast majority of magnetically based sensors use Reed Sensors or Hall Sensors, with general typical attributes for both shown below.

Both Hall Sensors and Reed Sensors play a major role in the magnetic sensor marketplace. Hall sensors are somewhat smaller solid state devices that always require external power and have the disadvantage of requiring external EDI protection as well as external switches and/or drivers to allow switching any appreciable electrical load. They do not in themselves have the ability to withstand external electrical surges.

Reed Sensors are usually somewhat larger compared to Hall Sensors but have a substantial amount of built-in power switching capability, typically having the ability to switch 10 VA. Versions of Reed Sensors have the ability to switch over 100 VA directly. They also have substantial ability to withstand electrical surges.

When applying these sensors in a specific application one must understand how the sensor sees the magnetic flux generated by the permanent magnet. Hall Sensors, to operate efficiently, must see the lines of magnetic flux generated by the permanent magnet perpendicular to a very small sensing area on the surface of the Hall Sensor.

Reed Sensors, on the other hand, have built-in flux concentrators as the external and internal parts of the Reed Sensor leads are manufactured from NiFe wire and act as antennas, searching for the flux generated by the permanent magnet. In addition, these external switch leads can be formed for fit in the end application in a manner that allows them to “grab” more of this magnetic flux, similar to how a keeper functions on a permanent magnet.

Because Hall sensors come in somewhat smaller packages they can be easier to place mechanically. On the other hand, Hall sensors are usually somewhat less magnetically sensitive when compared to Reed sensors. With a substantial amount of its lead material in place in the application, Reed sensors, because they have NiFe blades that look for magnetic flux can sometimes be placed mechanically in a magnetic circuit to take full advantage of this feature.

Applying magnetic sensors to get the most from the sensor in real world applications is somewhat of an art. To assist in this effort, some manufacturers have application design groups that can provide detail design assistance even for very complex magnetic circuits containing magnetic variables that are a part of electrical and mechanical systems where these sensors are intended to be used.

One of the more important technical services some manufacturers offer is magnetic circuit modeling and mapping. These systems allow one some guidance in an effort to properly place the various magnetic components mechanically in the end device.

Another tool appropriate in these magnetic sensor system designs is the use of a DOE (Design of Experiment) to allow looking at the total magnetic circuit in an analytical way. This process allows one to take into account all the important magnetic and mechanical system variables, looking at the effect each has on the proper operation of the sensor system.

Give us a contact today, to discover how we can partner to deliver smart solutions for your project! For more information, see our Magnetic Sensing Technologies Infographic.