“基于干簧开关的液位传感器是低功率设备,不需要复杂的电力支持,因此在大多数应用中非常有竞争力。”

如果您在某些方面需要帮助,请随时跳到以下任何部分:

介绍

斯丹麦德电子液位传感器

影响液位传感的环境趋势

结论

其他资源

电容式液位传感器(CLS)

霍尔效应液位传感器(HLS)

介绍

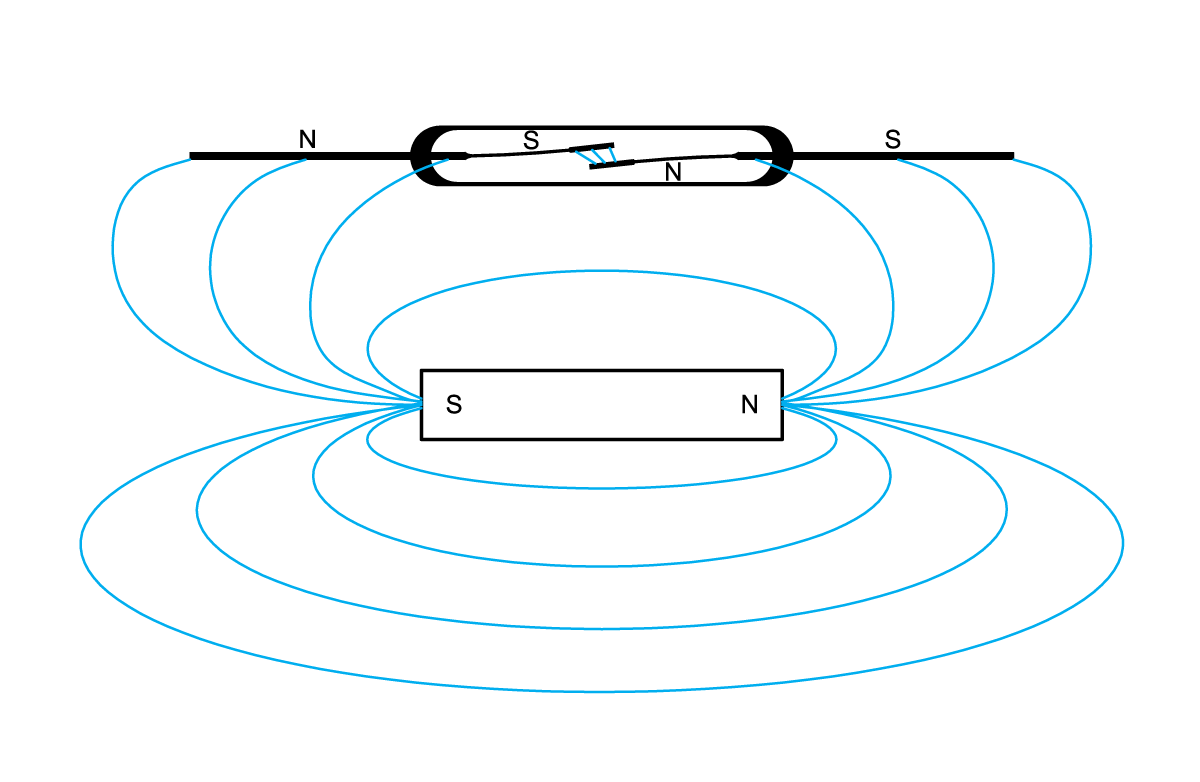

以前,液位传感器仅提供简单的开/关信号。然而,如今的传感器被要求提供大量复杂的信息。 住宅和工业设备应用监控管理的发展要求液位传感器更复杂、“更智能”。智能传感器的功能不只是打开和关闭,简单的干簧开关可以被设计成“更智能”的形式,以发出更多信息。 例如,在PCB上增加多个干簧开关可提供多个液位点测量;同样,在电路中放置电阻会产生离散的电压输出,这些电压输出用于指示沿磁浮子行进路径的许多可能的液位点,从而将干簧传感器设计成智能传感器。

如果客户需要数字或定制电压信号,则可以使用板载或远程信号电子设备来完成。传感器环境决定是使用简单的机械浮子传感器或是更复杂的传感器技术(电容或霍尔效应)。环境污染物会限制机械浮球液位传感器的运动。同样,电导率传感器极易发生电解。此外,导电传感器必须事先辨别是浸在液体中还是粘在探针上。

可调式多个液位传感器

斯丹麦德电子液位传感器

干簧开关液位传感器易于定制且易于安装。而且,它们是不需要复杂电子设的低功率配件,换句话说,干簧技术传感器在大多数应用中非常有竞争力。

第一个应用示例是制动液传感器,用于在油箱中发出危险的低汽车制动液液位信号。第二个示例是洗碗机溢满状态传感器,用于防止过度用水和外溢。在此示例中,干簧开关技术取代了微动开关。干簧开关和热敏电阻安装在PCB上,与由两个磁浮子组成的多合一液位传感器组合在一起。一个浮子和开关负责溢流保护时关闭洗碗机。另一个浮子在两个干簧开关之间移动,以提供多个液位读数。

由于客户现在期望的远不止液位传感器的开/关信号。液位传感器需要向最终用户提供智能信息,无论是警告危险液位还是只是为了方便。 每次设备运行时,现代洗衣设备都配备大量洗涤剂液位传感器。最重要的是,“智能”让客户体验更好用“、更便利。

影响液位传感的环境趋势

此外,环保计划是新传感器技术和应用发展的另一大推动力。单个和家用电器以及工业水箱的能量监控就是一个例子。如今,环境传感器还必须是具有无线和机器对机器(M2M)交互作用的“智能”设计,以便进行远程监控。这就是斯丹麦德电子引入创新,高质量可靠组件的地方,这些组件符合此类应用的要求。

想象一下,你正在休假,收到一条短信警报,说空调排水管的水泵停止工作了!那么你就可以立即对紧急情况做出响应,阻止了更大损坏的发生。只有带有板载电子设备的“智能”液位传感器才能提供此类警报。而斯丹麦德电子智能传感器设计可以满足这些高标准的传感要求。

此外,清洁水和水处理对于液位监测具有巨大的环境影响。实际上,发展中国家的水处理可能是液位传感器的最大市场。传感器应用包括下水道,灰色水和清洁水。液位传感器监控关键的用水量,以避免浪费。斯丹麦德电子可以满足美国国家科学基金会(NSF)法规的规范以及各种饮用水和食品服务应用对不锈钢传感器的要求。

结论

总而言之,如今液位传感器可以在远程或在设备级提供更智能,更准确的反馈。斯丹麦德产品可以使产品更智能,更高效和更高产。最重要的是,我们的智能传感器设计使用的能源更少,改善了资源管理,降低了成本并提高了性能。

最后,我们在磁感应技术和定制包装方面的专业工程团队可以为您提供满足您传感需求的一站式服务。立即与我们联系,商讨您的特定设计要求。

其他资源

了解有关我们的液位传感器功能的更多信息,请浏览液位传感器产品经理Elena Tischer关于的Thought Leadership访谈

更多资源请查看霍尔效应和电容式液位传感器解决方案。

霍尔效应液位传感器(HLS) | 电容式液位传感器(CLS) |